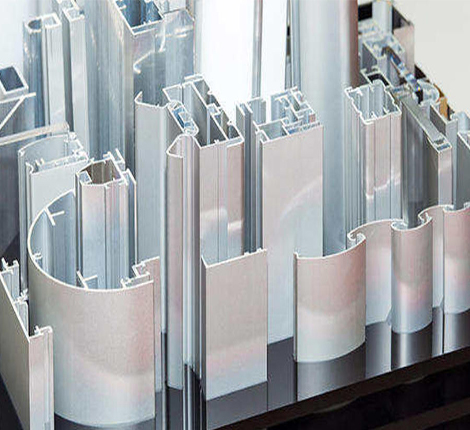

ALUMINIUM EXTRUSION

Extrusion is the most modern and very versatile method of forming Aluminium. The aluminium logs, after casting to the specified alloy the logs are sheared to the required billets size and then fed into the continuous homogenizing furnace wherein it is heated to a desired temperature. These are pushed under tremendous pressure, applied by a hydraulic ram, through a shaped aperture in a steel die. The die aperture may have almost any imaginable contour, thereby making it possible to produce infinite shapes and these sections are then stretched with lower loads in order to maintain straightness and to avoid bending failures. Later these sections can be sawed to the required lengths. It is possible to control the finish of the extruded sections to such a degree, during its passage through the steel die that no further finishing may be necessary, and if required,the part may be anodized straight away into attractive colors for higher consumer appeal.

One of the most widely used options to extrude aluminum alloys is alloy 6063, which offers a high quality finish and is an excellent option for extrusion. It is used for custom and standard aluminum extrusion design, as well as for structural pipes and tubes, seamless tubing, heat-sinks and much more.

Aluminium Extrusion Profile and Powder Coating

About Us

Kfore Extrusion Profiles - At a Glance:

We are one of the manufacturers and suppliers of aluminum extrusions since 2006 with enhanced cutting edge technologies improvising day by day.

Our Brink of Growth:

Our management is done by our Managing Director Shri.M.Ramesh Reddy, Who himself is Mechanical Engineer and Foreign Return. His Enthusiasm in this field is abundant and projected towards the continual development and improvement of day to day advancements.

By adapting to the fast paced changes we are maintaining the best-in-class standards. We aim to revolutionize aluminum manufacturing. Any visitor is marvelled at our engineering and the facilities at our Industry.

Recently we have also got certified for our contribution towards product quality management with Quality Management System ISO 9001:2015

Industry Information:

We are located at the Industrial Development Area Bhongir in Yadadri district. We import the raw material from NALCO, New Zealand, and Australia via our agents form Chennai.

We have our own furnace department where we make our own INGOTS for production with standard procedures followed all throughout the process.

We have two hydraulic Presses in our site where we extrude and produce desired sections according to the production orders. We are capable of producing 6 Tons per day. We followstrict quality policy for our beloved customers with which there will be a good stream line of business. “Out of Quality is Out of Business” is our motto.Our technical advancement integrated with field knowledge and engineering expertise allows us to develop innovative products. Our company’s wide ranges of products are used in construction, transport and electrical fields. We have kept advanced technology in all applications which produces high quality products.

Each and every personal is trained to maintain quality with no compromise at every end in the industry. We do follow strict rules of safety and compliance to ensure complete care and control of the Industry, Equipment and employees. Our products are well known for, its quality and are considered best among others in the country.

Our Valued Customers:

We have supplied major quantity of our products to our Customers like ALDUCT, NUMRO CONSTRUCTIONS, GMR, BRIGHTSTAR, INTERGLAZE and many more in and around Hyderabad.